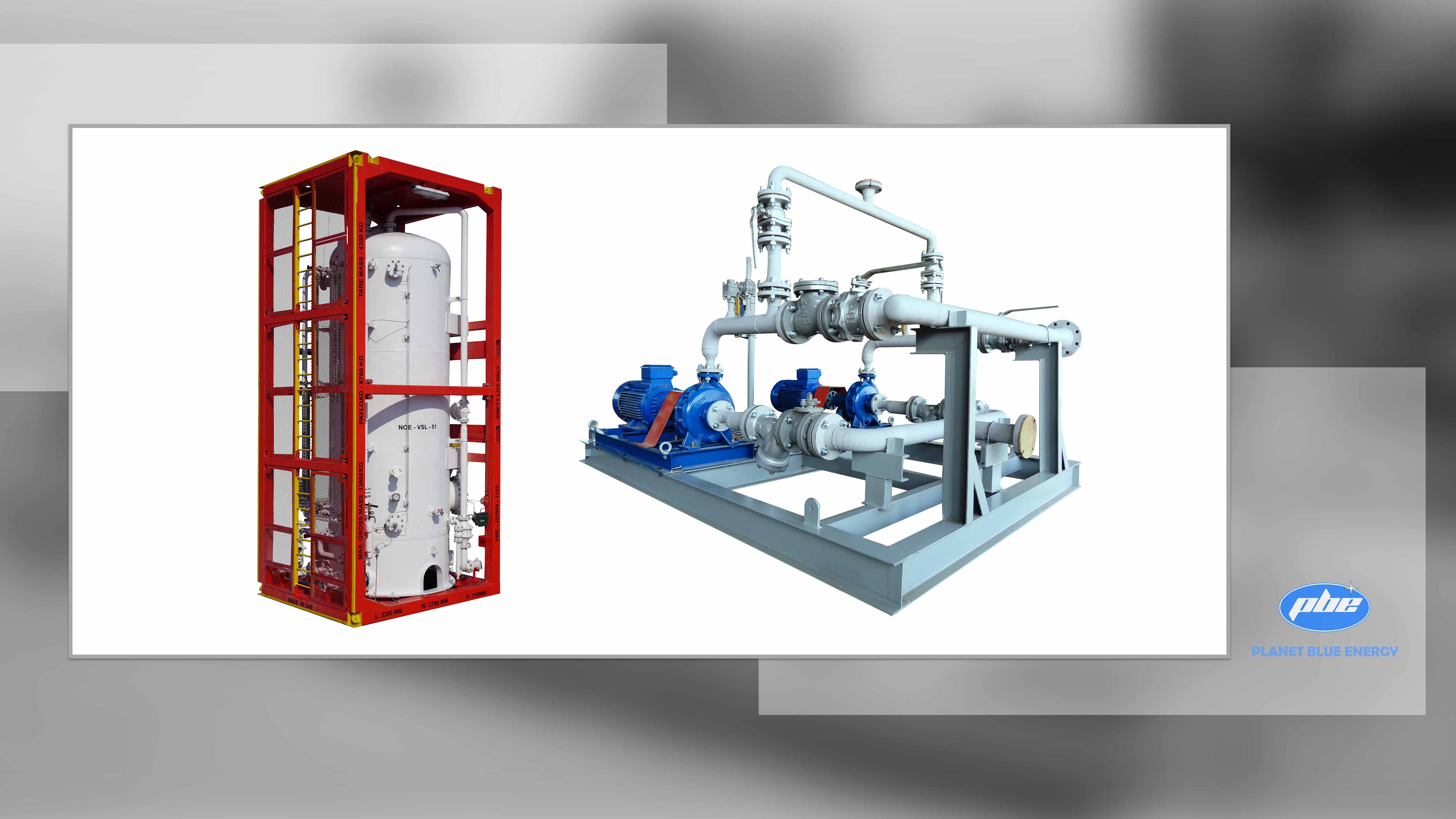

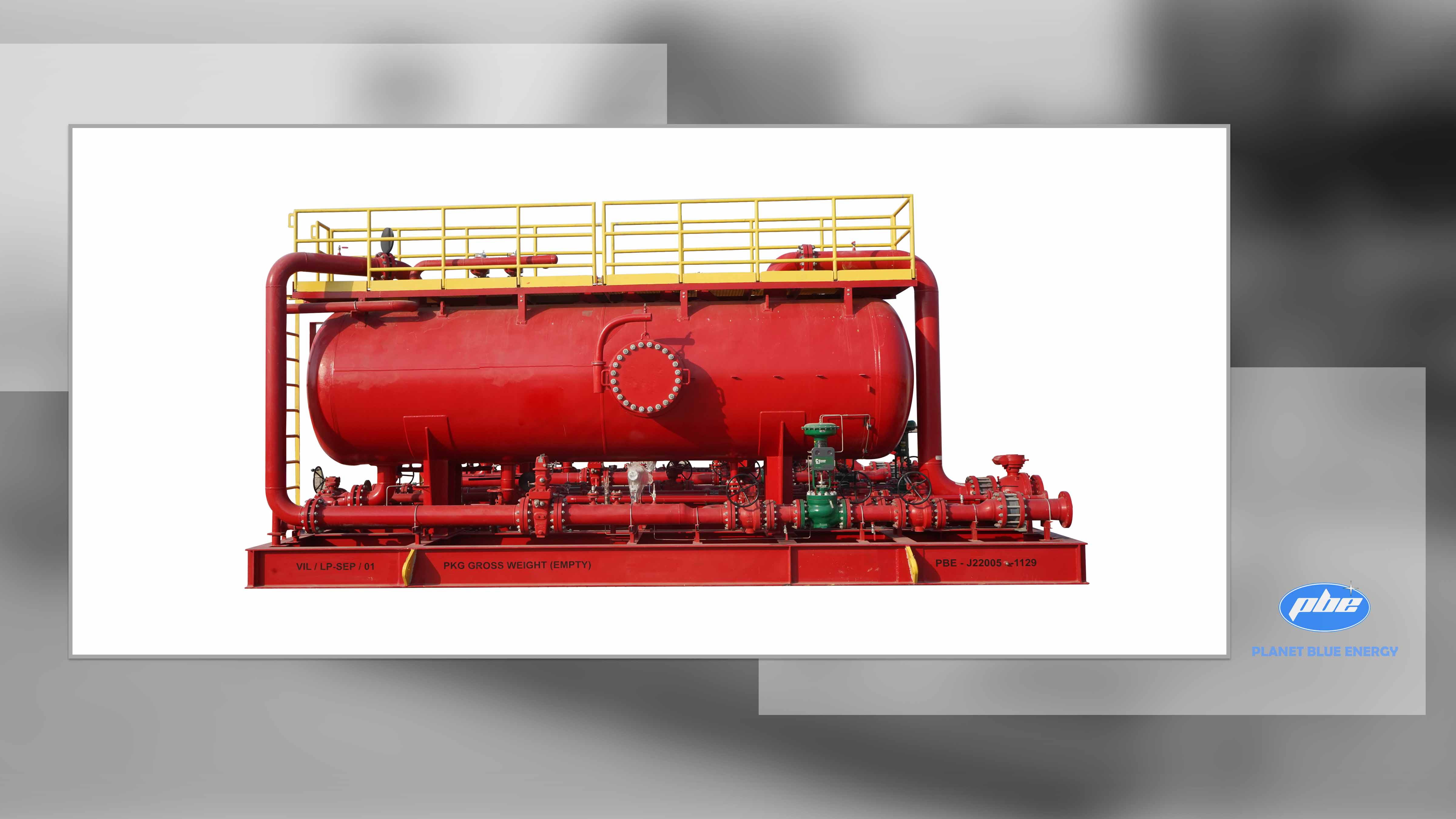

Production / EPF Facility

Our company specializes in designing and manufacturing crude oil production and early production facilities with capacities ranging from 5,000 to 40,000 barrels of oil per day (BOPD). These facilities are crucial for processing crude oil through various stages including separation, heating, dehydration, stabilization, storage, metering, and pumping before it is transferred to storage tanks. As part of these facilities, we provide a comprehensive range of equipment to facilitate these processes efficiently and effectively.

- Manifolds

- Water Bath Heaters

- Separators

- Degassers

- N2 Strippers

- Electrostatic De-Salters

- API Storage Tanks

- Knock Out Drums

- Flare Packages

- Chemical Injection Skids

- Crude Oil Stabilizers

- Transportation Tanks

- Metering Skid Packages

- Pumping Skids

- Heat Exchangers

GAS COMPRESSION AND DEHYDRATION FACILITIES

We Design and Manufacture gas compression packages and natural gas treatment packages. Gas compression packages are essential for removing natural gas from oil and increasing the temperature of the gas during compression. This process ensures efficient separation of gas and oil components. Additionally, your natural gas treatment packages are crucial for removing water from natural gas using either liquid desiccants or dry desiccants in desiccant dehydration processes. These packages play a vital role in ensuring the quality and purity of natural gas for various industrial applications.

OUR GAS COMPRESSION AND DEHYDRATION PACKAGES INCLUDES

- Gas Compression Skids

- Gas Dehydration Units

- Gas Sweetening Units

- Amine Treatment Units

PRODUCED WATER TREATMENT FACILITIES

Our Produced Water Treatment Packages are designed and manufactured with a focus on optimizing produced water management, maintaining quality levels, aligning with production forecasts, and adhering to design, build, and operational limitations. These packages offer engineered solutions tailored to meet your clients’ requirements for handling, production, disposal, and enhanced oil recovery, all while complying with high-quality standards. This comprehensive approach ensures efficient and effective treatment of produced water, contributing to environmental sustainability and maximizing the value of oil production operations.

COALESCER FILTERS SKIDS

- Hydro cyclone Separation Skids

- Gas Floatation Units and IGF Vessels skids

- Degassers Skids

- Coalescer Filters Skids